Forno de recozimento de precisão de tiras de vidro óptico tipo correia de malha

| Uso do equipamento |

Para garrafas de vidro, vidro e outros utensílios e frascos de cosméticos de vidro, etc.

Para iluminação de vidro, vidro diário, prensagem de vidro (frio) recozimento

|

| Temperatura máxima |

750 ° C |

| Temperatura usual |

500-600 ° C |

| Comprimento do forno |

18M-36M |

| Tamanho do forno |

Largura 300mm-2500mm, altura 120mm-350mm (pode ser personalizado de acordo com o cliente) |

| Velocidade de execução |

0 ~ 500mm / min (ajustável continuamente) |

| Largura da correia de malha |

300mm-2500mm |

| Material da tira da correia |

Aço inoxidável SUS304, SUS321 |

| Ponto de controle de temperatura |

5 ~ 20 pontos |

| Modo de controle de temperatura |

Controle independente sub-regional |

| Precisão da temperatura de controle do instrumento |

± 1 ° C |

| Temperatura uniforme no forno |

≤ ± 5 ° C |

| Aquecedor |

Tubo de quartzo ou forno elétrico |

| Sistema de controle de temperatura |

Sistema de controle de temperatura inteligente PID, interface de controle de tela sensível ao toque |

| Recursos |

1. A precisão da temperatura no forno é precisa, a homogeneidade da temperatura do forno é alta e a consistência do produto é boa.

2, A operação do equipamento do dispositivo de tensionamento da correia de malha pneumática é estável.

3, Toda a estrutura da placa de algodão de aquecimento de fibra cerâmica, aumento rápido da temperatura, economia de energia é eficiente.

|

| Observações |

Os parâmetros acima são apenas para referência, este equipamento é um equipamento não padronizado, que é personalizado de acordo com os requisitos reais do processo do produto. |

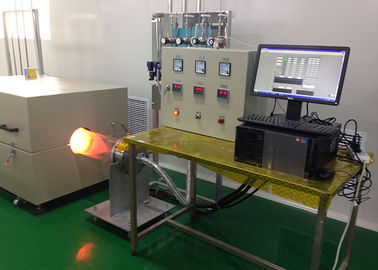

Lehr de decoração de combustível de vidro tipo correia de malha para artigos de vidro

1, Visão geral do produto

Este lehr é usado principalmente para garrafas de vinho de vidro, artigos de vidro, vidro diário e vidro de processo, decoração de marca registrada de alta temperatura (papel manchado) e decoração de ouro; o comprimento total do forno é de 28 a 40 metros; a temperatura máxima de uso é de 650℃; e é adequado para produção contínua em larga escala.

2, Tabela de atributos de parâmetros

1. Comprimento do Lehr: 10-32m

2. Potência inicial: 30-270Kw/380V

3. Método de transferência: correias de malha de aço inoxidável 304 / 321, regulação de velocidade de conversão de frequência.

4. Largura da correia de malha: 300-4000mm

5. Temperatura máxima de uso: 750℃

6. Precisão do controle de temperatura: ±1℃

7. Modo de controle: sistema de controle inteligente PID, controle multiponto.

8. Circulação de ar quente: Largura da correia de malha ≥1,2m pode ser considerada por circulação de ar quente

9. Estrutura do Lehr: Modular; montagem no local

3, Uso do produto

- Equipamento personalizado não padronizado, usado principalmente para artigos de vidro de uso diário, como garrafas de vidro, xícaras de vidro e outros produtos de vidro, decoração de alta e baixa temperatura (tinta de vidro de alta temperatura, papel de desenho)

- Também pode ser usado para: vidro de uso diário, vidro prensado, vidro de iluminação e outros tratamentos térmicos de recozimento a frio e a quente.

4, Recursos gerais

O processo de produção é que o produto é colocado na correia de malha, acionado pela correia de malha e aquecido da extremidade de alimentação para o forno, através da abertura do forno para formar, depois resfriado gradualmente pela câmara de resfriamento e, em seguida, coletado pela extremidade de descarga para completar todo o processo de tratamento térmico.

Entre em contato conosco para obter detalhes, faremos sob medida para você!

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!